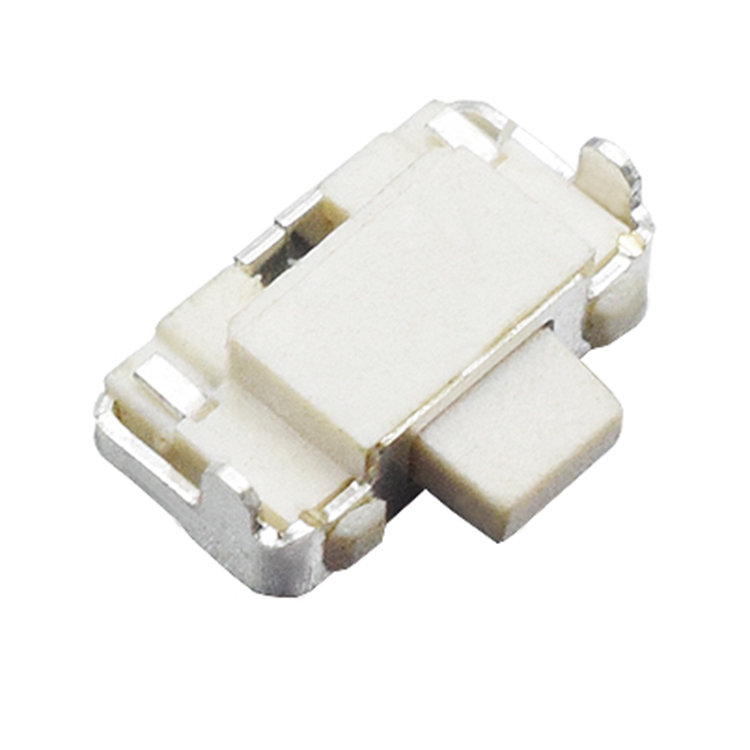

HOT SALE Tactile Switch 2*4 Sunk Panel SMD/SMT Side Press 2 Pin Button Switch Tact Switch With Stents

Product advantages: fast delivery, free samples, the switch with ROHS 2.0 and CE certification, life time is more than 300000 times, small volume, high temperature resistance of patch, good press feeling and rebound, technical support and best sales service.

Application fields: mobile communication products, wearable watches, instruments and equipment, consumer electronics, household appliances, security products

Factory strengths: with 13 years of industry experience, the company has passed ISO9001 certification, a number of patent certificates, more than 5300 cooperative customers, many customers of listed companies, 106 employees, 12 hardware punches, 18 injection molding machines, 26 full-automatic assembly machines, 32 full-automatic testing machines, 21 semi-automatic testing machines, 12 life testing machines and 25 other testing equipment

Operating Life

Measurements shall be made following

the test

set forth below:

(1) DC 12V 50mA resistive load

(2) Rate of operation : 2 to 3 operations

per second

(3) Depression 250±50gf

(4) Cycles of operation >30,000 次。

1-Contact resistance: 1000mΩMax

2-Insulation resistance

10 MΩ min.3-action force attenuation rate was 15% of the initial value

Vibration Resistance

Measurements shall be made following the test set forth below:

(1)Range of oscillation: 10~55 Hz

(2)Amplitude pk to pk : 1.5mm

(3)Cycle of sweep : 10-55-10Hz in one minute

(4)Mode of sweep : Logarithmically sweep or uniform sweep.

(5)Direction of oscillation: Three mutually perpendicular directions, including the direction of stem travel.

(6)Duration of testing 2 hours each ,for a total of 6hours..

Impact Shock Resistance

Measurements shall be made following the test set forth below:

(1) Acceleration 80g

(2) Cycles of test :3 cycles each in 6 directions.for a total of 18 cycles.

Reflow soldering conditions

Preheat: Temperature on the copper foil surface should reach 180℃,2±0.3 minutes after

The P .W. B entered into the soldering equipment.

Soldering heat: Temperature on the copper foil surface should reach the peak temperature of 265℃

within 20 seconds after the P.W.B entered into soldering heat zone.